RubberMat Co 4 inch Mat Analysis

California Bearing Ratios vs Drilling Rig Platform Performance

Let’s utilize sun, wind and water in a better way

Condimentum pede quis etiam suscipit montes luctus adipiscing. Vivamus mattis cursus rhoncus cubilia nisl enim morbi tellus lorem sollicitudin. Cursus tempus quisque elementum id metus phasellus porta suscipit malesuada. Praesent egestas metus facilisis dictum mollis ullamcorper imperdiet elementum malesuada justo vulputate.

Preface (RubberMat Co)

Mat Material Properties Table

| Thermoplastic Resin | Steel Mesh | ||

Modulus of Elasticity | E | ksi |

| 31910 |

Shear Modulus | G | ksi |

| 11850 |

Yield Strength | σy | psi |

| 30020 |

Tensile Strength | σt or σc | psi | 680 | 50040 |

Poisson’s Ratio | u | unitless | 0.360 | 0.280 |

Soil properties were determined using California Bear Ratio (CBR) guidelines. CBR strength tests yield a value for comparing load bearing capacity of a sub grade material to that of well graded crushed stone. The American Association of State Highway and Transportation Officials (AASHTO) published the Mechanistic Empirical Pavement Design Guide (MEPDG) in 2008. AASHTO MEPDG uses the formula below to convert CBR to resilient modulus (MR) (in psi), which is itself an approximation of modulus of elasticity.

MR ≅ 2555 × CBR0.64

Soil Material Properties Table (assumed to be temperature independent)

California Bearing Ratio | CBR | unitless | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Soil Poisson’s Ratio | u | unitless | 0.350 | 0.350 | 0.350 | 0.350 | 0.350 | 0.350 | 0.350 | 0.350 | 0.350 | 0.350 |

Soil Density (est) | r | lb/cu in | 0.048 | 0.055 | 0.062 | 0.069 | 0.077 | 0.084 | 0.091 | 0.098 | 0.105 | 0.112 |

Soil Modulus of Elasticity | E | psi | 2555 | 3980 | 5160 | 6200 | 7160 | 8050 | 8880 | 9670 | 10430 | 11160 |

At the request of RubberMat Co, loading produced by three different rigs were to be considered in the analysis. The major task in processing the rig information was to identify the location and magnitude of the greatest ground pressure produced by the various modular components used in the drilling process. The rig loads to

be analyzed were based on a Major Drilling Rig Supplier (specifically for Drilling Rig Sizes: SINGLE, DOUBLE and TRIPLE load rating were used ). Unfortunately, the rig information provided was not accurate. As a result, major assumptions and estimations were made during process of establishing relative ground pressures produced by different rig components. The results for DOUBLE rig are noted to be the most accurate of the three rigs and can be considered quantitatively correct.

The analysis of DOUBLE rig showed that the actual drilling assembly (consisting of the substructure, mast assembly, drill floor, drawworks, etc.) coupled with the static hook load, was easily the most intensely loaded component of all the rig’s modules. The mat analysis was based on the ground pressure produced at the underside of the frame rails of the substructure.

In order to complete this project for the other two rigs (SINGLE and TRIPLE) Genmark estimated the weights of the respective drilling assemblies by comparing the static hook load of DOUBLE rig to the weight of its drilling assembly structure, and created a ratio using the hook loads of each rig compared with that of DOUBLE rig. The results generated for SINGLE and TRIPLE Rigs are accurate, however they lack precision due to the missing weight information. As a result,these weights cannot be considered quantitatively correct or precise.

It is the opinion of Genmark that the information generated in the analysis of the ground pressure loads produced by SINGLE and TRIPLE Rigs are useful guidelines for the purpose of selecting the number of required mat layers based on site soil conditions (CBR). If better information is forwarded to Genmark in the future, it is possible to re‐perform the analysis and amend this document to include any changes mandated by the new data.

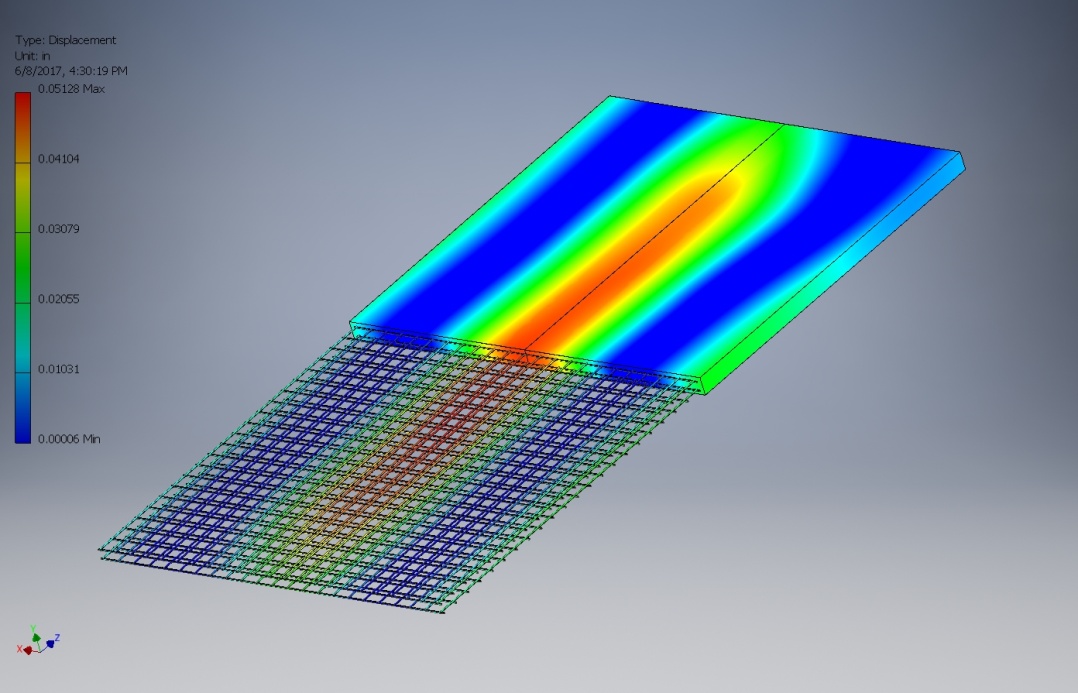

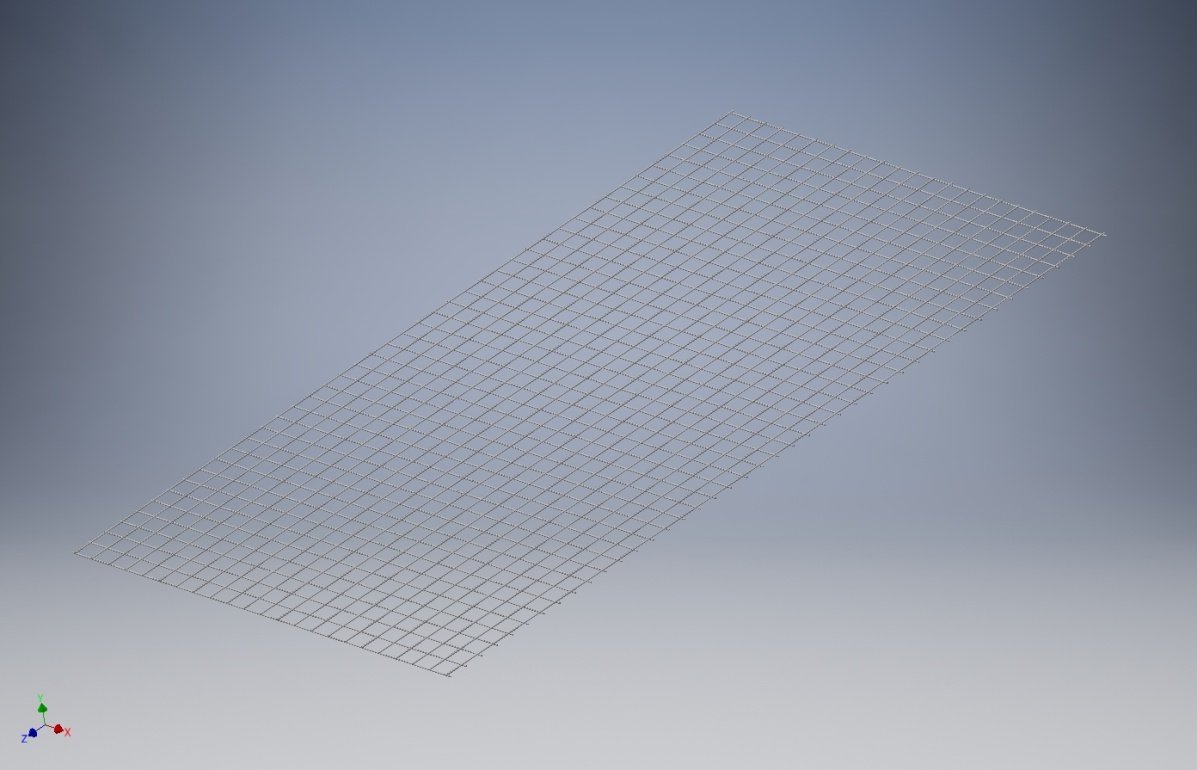

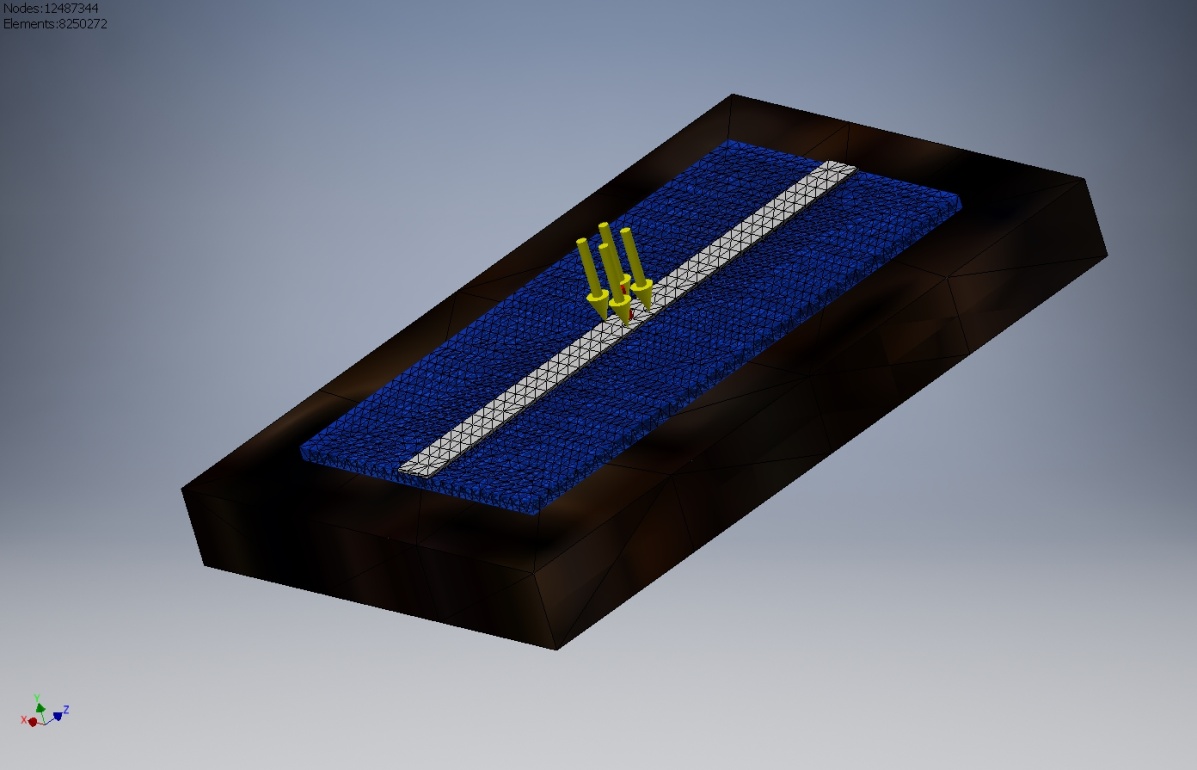

Typical Mat Loading (10 soils x 3 Rig Loads = 30 tests)

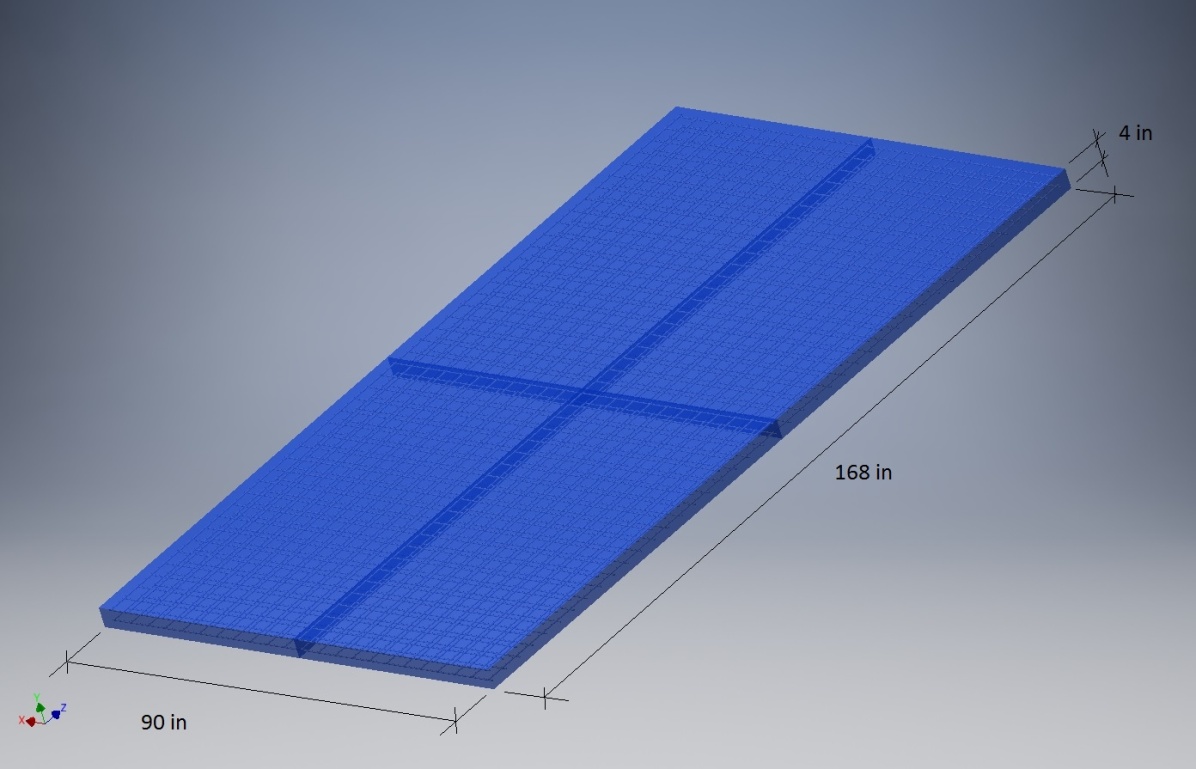

4 inch Mat Assembly ‐ Complete

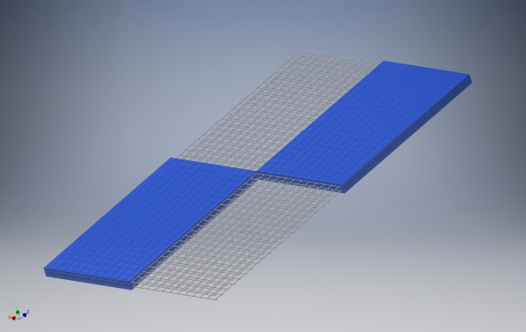

4 inch Mat Assembly ‐ Thermoplastic Resin is partially removed

4 inch Mat Assembly ‐ Thermoplastic Resin is fully removed

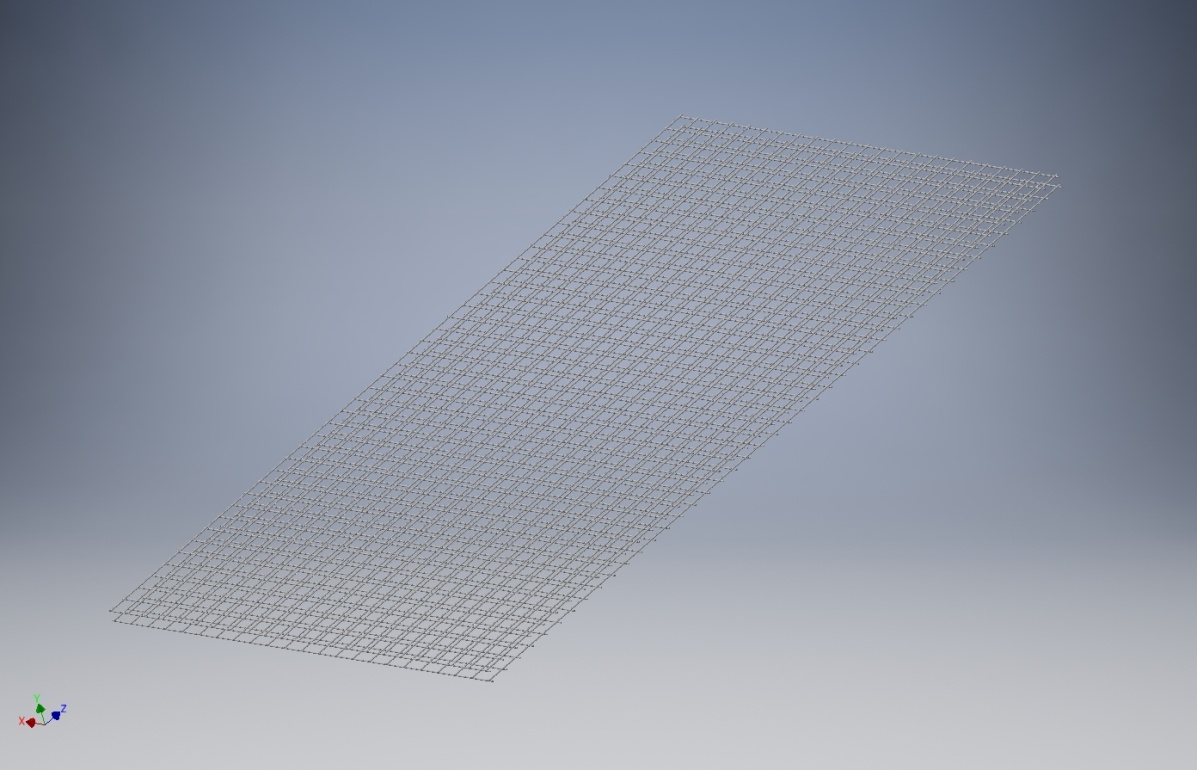

4 inch Mat Assembly ‐ Thermoplastic Resin and One Layer of Mesh removed

Typical Mat Loading and Mesh

Introduction

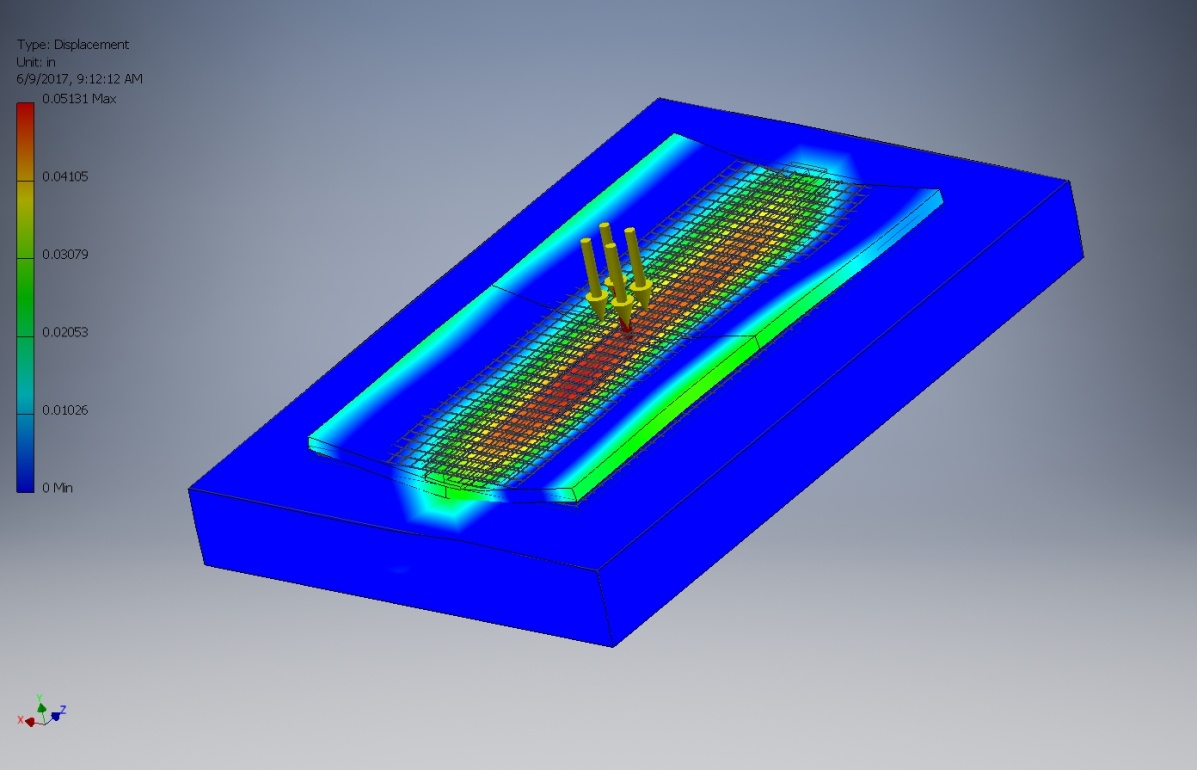

Soil properties were determined using California Bear Ratio (CBR) guidelines. Material models simulating the properties of soil with California Bearing Ratios of 1 through 10 were tested with anticipated maximum loads produced by the three respective drilling rigs.

As complete data was provided for DOUBLE Rig, this enabled Genmark to produce precise results. Results for SINGLE and TRIPLE Rigs are based on estimated module weights, and while accurate, these results could be skewed if the actual component weights are much different from those used in the analysis.

Rig Specifications

SINGLE RIG

- Static Hook Load: 111200 daN (250000 lb)

- Drilling Assembly Weight: 265400 lb (Estimated)

- Total Load Through Substructure: 515400 lb (Estimated)

- Substructure Skid Beam Contact area ‐ 103.6 sqft (Estimated)

- Contact Pressure = 515400 lb / 103.6 sqft = 4975 lb/sqft = 34.5 psi

DOUBLE RIG

- Static Hook Load: 333600 daN (750000 lb)

- Drilling Assembly Weight: 796250 lb

- Total Load Through Substructure: 1546250 lb

- Substructure Skid Beam Contact area ‐ 155.4 sqft (Provided)

- Contact Pressure = 1546250 lb / 155.4 sqft = 9950 lb/sqft = 69.1 psi

TRIPLE RIG

- Static Hook Load: 444800 daN (1000000 lb)

- Drilling Assembly Weight: 1061700 lb (Estimated)

- Total Load Through Substructure: 2061700 lb (Estimated)

- Substructure Skid Beam Contact area ‐ 155.4 sqft (Estimated)

- Contact Pressure = 2061700 lb / 155.4 sqft = 13267 lb/sqft = 92.1 psi

Loading Summary

Single Rig | P | psi | 34.5 |

Double Rig | P | psi | 69.1 |

Triple Rig | P | psi | 92.1 |

Allowable Deflection | δ | in | 0.375 |

Allowable Stress Resin | σall_r | psi | 410 |

Allowable Stress Steel | σall_s | psi | 18084 |

Allowable Deflection and Stresses in different Mat Materials

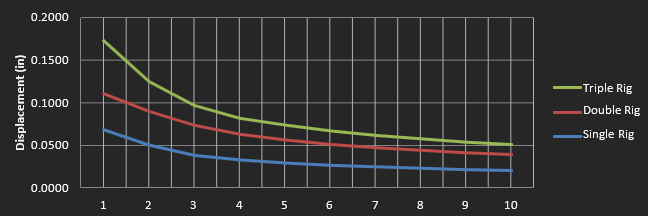

The following are results of Genmark's exhaustive analysis:

FEA Results for 4 in Mat Displacement | |||

California Bearing Ratio | Single Rig | Double Rig | Triple Rig |

d ‐ deflection (in) | |||

1 | 0.0679 | 0.1108 | 0.1727 |

2 | 0.0500 | 0.0900 | 0.1250 |

3 | 0.0381 | 0.0735 | 0.0970 |

4 | 0.0329 | 0.0630 | 0.0820 |

5 | 0.0293 | 0.0562 | 0.0741 |

6 | 0.0266 | 0.0510 | 0.0672 |

7 | 0.0246 | 0.0470 | 0.0620 |

8 | 0.0230 | 0.0440 | 0.0580 |

9 | 0.0215 | 0.0410 | 0.0540 |

10 | 0.0206 | 0.0390 | 0.0513 |

Full Mat Deflection Summary (10 CBR's and 3 Loads)

Displacement vs. California Bearing Ratio, 4 inch Mat (Full Mat)

Typical Mat Deflected Shape

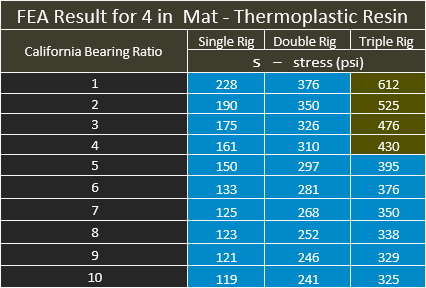

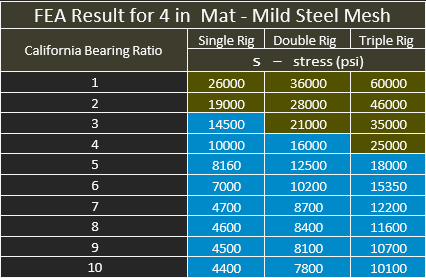

Thermoplastic Resin Stress Summary (10 CBR's and 3 Loads)

Stress vs. California Bearing Ratio, 4 inch Mat ( Thermoplastic Resin)

Based on the above results, thermoplastic resin stresses are good for the imposed conditions for:

- All CBR values and single rig loading conditions.

- All CBR values and double rig loading conditions.

- Triple rig loading conditions and CBR from 5 to 10.

All stresses that are below 410 psi ‐ are acceptable (blue color in the table)

All stresses that are above 410 psi ‐ are not acceptable (yellow color in the table)

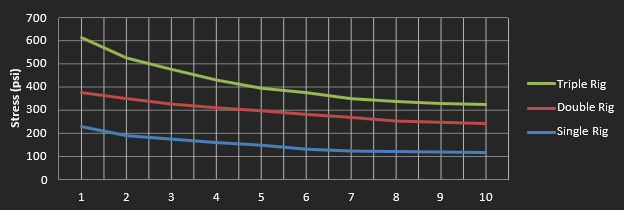

Thermoplastic Resin Stresses (typ)

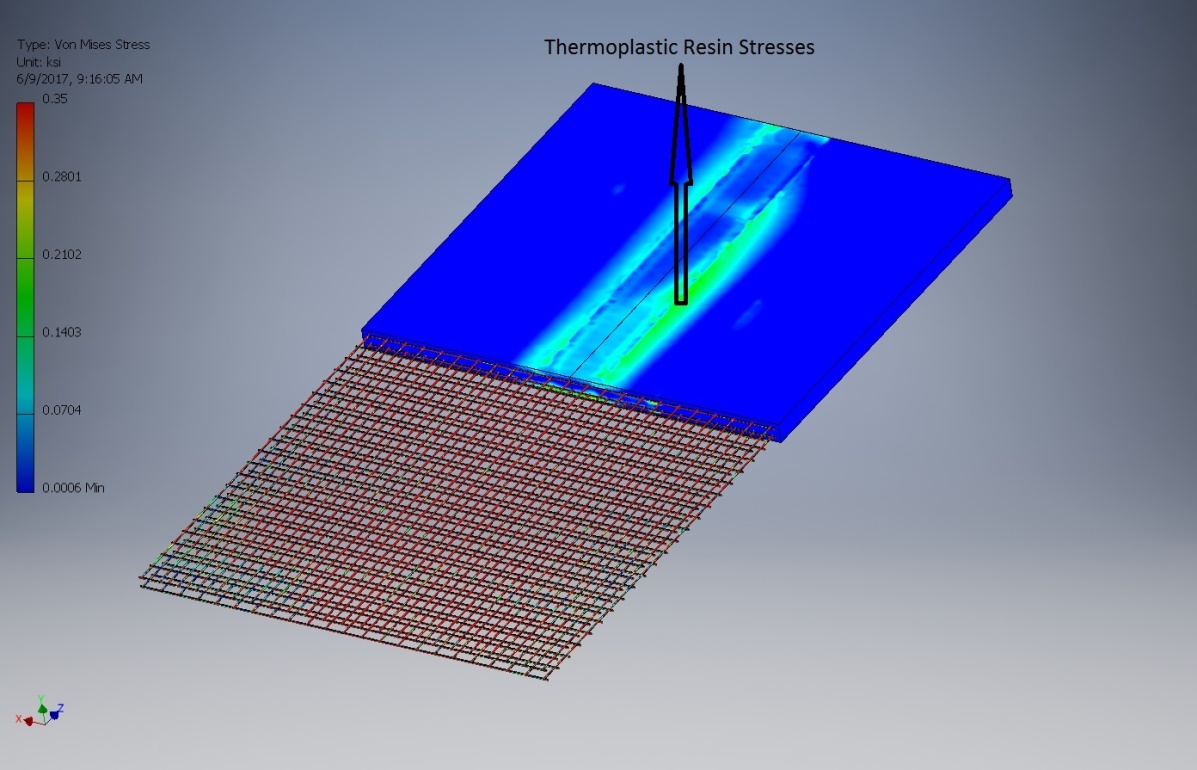

Steel Mesh Stress Summary (10 CBR's and 3 Loads)

What we offer

Keep your environment clean make the earth green.

Letius imperdiet vivamus sodales molestie amet primis eget scelerisque vitae porttitor hendrerit.

Letius imperdiet vivamus sodales molestie amet primis eget scelerisque vitae porttitor hendrerit.

Letius imperdiet vivamus sodales molestie amet primis eget scelerisque vitae porttitor hendrerit.

Letius imperdiet vivamus sodales molestie amet primis eget scelerisque vitae porttitor hendrerit.

Letius imperdiet vivamus sodales molestie amet primis eget scelerisque vitae porttitor hendrerit.

Letius imperdiet vivamus sodales molestie amet primis eget scelerisque vitae porttitor hendrerit.

Why Choose Us

Empowering Your World with Reliable Solutions.

Integer augue fames eget sollicitudin ullamcorper ultricies curae.

Integer augue fames eget sollicitudin ullamcorper ultricies curae.

Integer augue fames eget sollicitudin ullamcorper ultricies curae.

Featured Project

Keep your environment clean make the earth green.

Justo dictumst id semper taciti lacus tortor per si habitasse platea vestibulum.

Justo dictumst id semper taciti lacus tortor per si habitasse platea vestibulum.

Justo dictumst id semper taciti lacus tortor per si habitasse platea vestibulum.

Justo dictumst id semper taciti lacus tortor per si habitasse platea vestibulum.

Justo dictumst id semper taciti lacus tortor per si habitasse platea vestibulum.

Justo dictumst id semper taciti lacus tortor per si habitasse platea vestibulum.

Book an Appointment

Let’s experience the power of the sun.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- 100% renewable content from wind or solar energy.

- Free electricity during nights or weekends.

- Access to local solar energy without the need to install rooftop panels.

- Resources to green up your life, including Tree Free Billing, carbon offsets and weekly summary emails.