Rubber mat

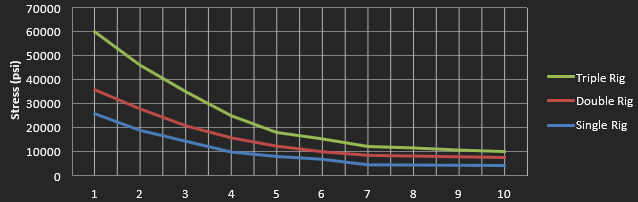

Stress vs. California Bearing Ratio, 4 inch Mat (Mild Steel Mesh)

Based on the above result, Steel Mesh stresses are good for the imposed conditions for:

- Single rig loading conditions and CBR from 3 to 10.

- Double rig loading conditions and CBR from 4 to 10.

- Triple rig loading conditions and CBR from 5 to 10.

All stresses that are below 18084 psi ‐ are acceptable (blue color in the table)

All stresses that are above 18084 psi ‐ are not acceptable (yellow color in the table)

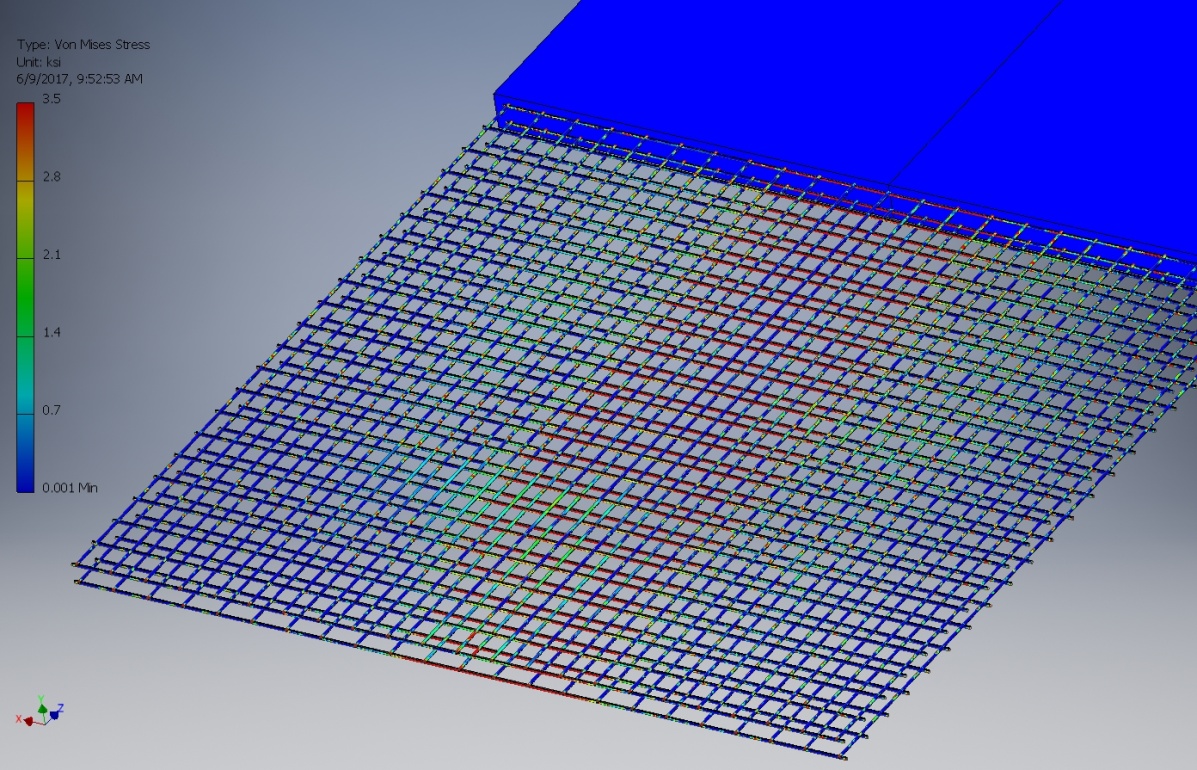

Steel Mesh Stresses (typ)

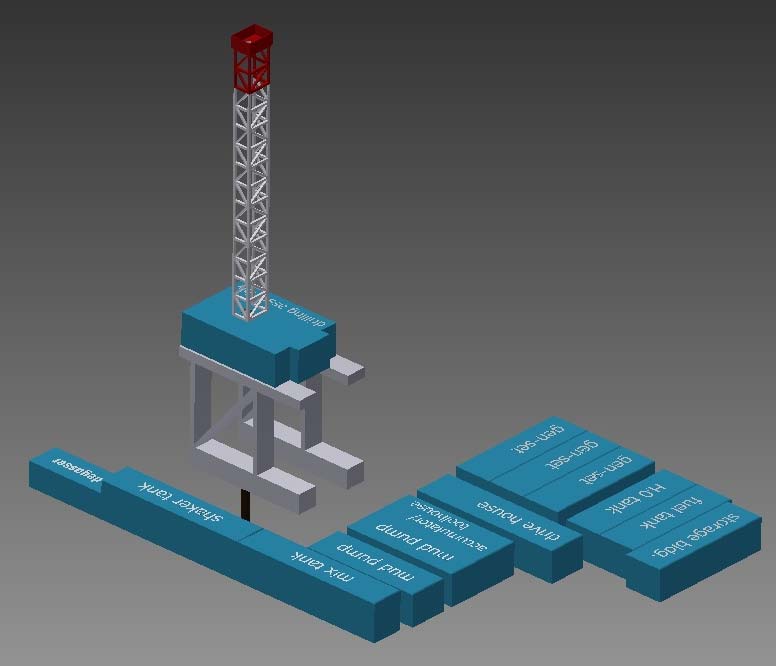

RubberMat Co 4 inch Mat: Final Performance Summary

The following are based on above analysis:

- The RubberMat Co 4 inch Mat is a viable solution for improving rig stability in soft soil conditions (CBR 1 through 10).

- As CBR increases, mat performance increases.

- As a load increases, mat performance decreases.

- Single Rig can be safely operated with a single layer of mats at CBR 3 and higher. A CBR of 1 and 2 using double layer of mats was not tested due to restrictions in computing power, and as a result, just assumed. Restriction is based on 19000 psi stress in steel mesh.

- Double Rig can be safely operated with a single layer of mats at CBR 4 and higher. A CBR of 1 to 3 using double or even triple layer of mats was not tested due to restrictions in computing power, and as a result, just assumed. Restriction is based on 21000 psi stress in in steel mesh.

- Triple Rig can be safely operated with a single layer of mats at CBR 5 and higher. A CBR of 1 to 4 using double or even triple layer of mats was not tested due to restrictions in computing power, and as a result, just assumed. Restriction is based on 25000 psi stress in in steel mesh.

- For applications with changeable soil conditions such as flooding or freeze/thaw cycles, Genmark recommends adding an additional layer of mats under Double and Triple Rigs.

- It is recommended to use weight comparison and estimate mat layer requirements for all other rig components.

- Minimum earth‐work on very loose soils will make a large difference in mat longevity, performance & rig stability.

- Examination of mats after use in heavily loaded areas is recommended. If possible, it should be determined if any permanent bending (plastic deformation) has occurred.

- Mildly damaged mats may be reused in light duty roles but should be marked appropriately.

- Surface abrasions from a module's bottom flange of its contact rails may occur if the flange edges are sharp. External damage may provide clues as to the condition of the internal rebar. It is recommended that an inspection of areas with external damage be completed carefully for signs of internal damage.

- If rebar is exposed or mat is permanently crimped or misshapen, the recommendation is to remove from duty at once.

Happy Client

0

K+

Pro Technician

0

K+

Wind Farms

0

M+

Solar Farms

0

M+